My classic car is leaking oil (V) - Engine breather problems preventing proper crankcase ventilation

When it is essential to solve the cause and not to alleviate the consequence

In the world of classic cars, a small oil stain under the car is often accepted almost as a medal of authenticity or at least as an unavoidable evil. In many cases, it certainly is, and fortunately they are minor evils that we can alleviate.

But there are nuances, as I mentioned in the previous parts of this article, where the cause must be sought.

Phantom" oil level drops - where can they come from?

When leaks or oil level drops start to be more than symbolic, they have to be checked in detail. The usual investigation usually focuses on seals, gaskets or loose screws, once the possibility of an internal problem (such as poor cylinder sealing or other anomalies that require the engine to be opened) has been ruled out.

And in these investigations where the origin of the oil level drop is difficult to identify, and becomes almost “phantom drop”, what is rarely considered is that the problem lies in how the engine breathes and the evacuation of internal oil vapors.

The crankcase ventilation is that discreet system that hardly anyone checks, and yet it can be the silent culprit of persistent leaks, abnormal oil consumption or curious situations in which, for example, the oil dipstick “jumps” without anyone knowing why. Many owners then believe that the problem is in the dipstick, thinking that it is defective, when in fact this is not the cause, but the consequence of an engine that literally tries to expel pressure wherever it can.

In a combustion engine, a small part of the gases in the chamber pass between the piston rings and down into the crankcase: this is known as blow-by. You can take a look at this link where you can see it very well schematically.

This mixture of gases and steam from the hot oil increases the internal pressure, and if not properly evacuated, ends up pushing the oil through any weak point: seals, oil seals or even the dipstick.

The mission of the crankcase ventilation system is as simple as it is vital: to keep the internal pressure balanced and allow these gases to escape without entraining oil.

The problem of the oil level control of our Renault Dauphine Gordini

That problem of lack of ventilation was what happened to our Renault Dauphine Gordini: A freshly rebuilt engine -reground block, new crankshaft, new liners, pistons, oil pump, crank and main bearings, new cylinder head, new crankcase- everything new, everything perfect on the bench… until a freeway trip started to show the problem of “external” oil leaks. Only on the highway. Problem that had already happened in the past-.

Why had the engine had to be rebuilt?

So making a chronological summary, this is what happened:

First failure:

- After about 100 km on the highway: oil leakage due to a broken crankshaft pulley seal. Not a catastrophic failure because it became visible when the car was stationary.

- Assuming an old oil seal as the cause, it was replaced (and we also took the opportunity to change the timing pinion).

- A few tests, no leakage problems and we considered the failure resolved.

Second failure:

- New exit to the highway after a couple of weeks for a long transfer of the vehicle. Apparently everything normal on the road.

- Suddenly, after about 200 km, the oil pressure suddenly dropped to zero, and you could hear the rattling noise in the engine that indicates that something very bad has happened inside the engine. It stopped immediately, but the damage was done.

- The crankcase was almost completely emptied. Causing very serious damage to the engine (destroyed crankshaft crankpins, melted connecting rod bushings). Destruction of the lower part of the engine.

- But the curious thing is that the oil had not come out of a specific point, neither through a broken crankcase nor through any visible gasket: there was oil literally everywhere. In other words, the rear part of the engine was simply soaked, as if it had been sprayed: the engine literally seemed to have “blown” its own oil out.

What could have happened? Hypothesis of the moment.

At the time it was attributed to a possible crack in the crankcase, deteriorated seals or even to an additive that had been added days before to “clean” the lubrication circuit.

Be that as it may, as the engine had to be completely disassembled for repair, the reason for the ultimate cause was put on the back burner, assuming that the total rebuild would eliminate it, whatever it might have been.

Renault Dauphine Gordini engine rebuilding

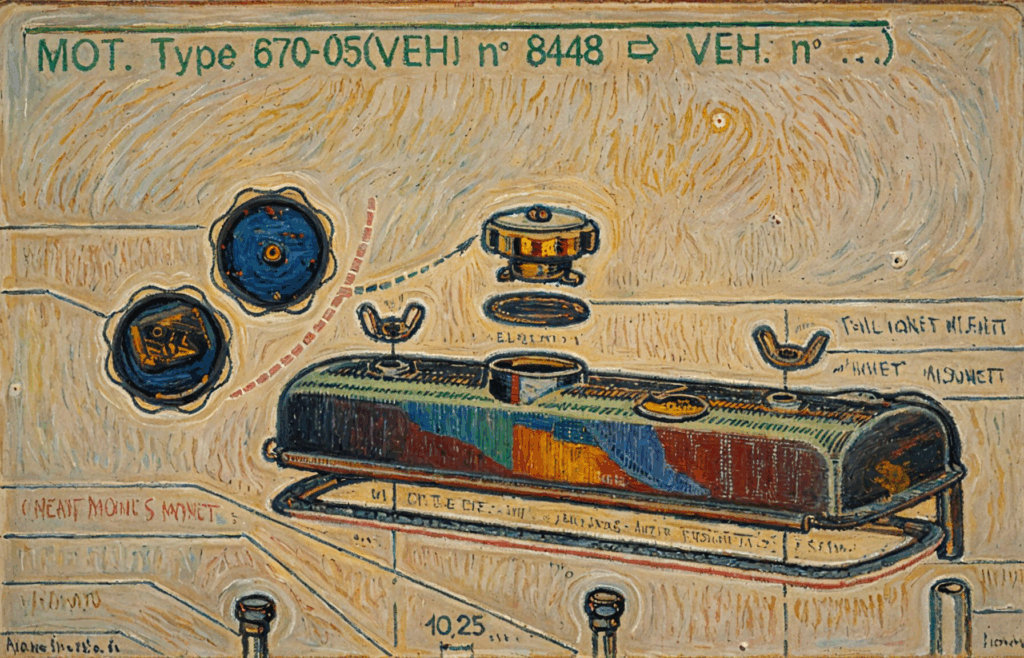

The second failure led to the need to rebuild the engine. We changed crankshaft (for a completely new one from old stock, a real unicorn found), bushings, liners, pistons, rings, oil pump, water pump, crankcase, block and cylinder head went through a rectifier, and a lot of auxiliary elements. I leave below a few photos, as a small sample of the process.

If you are in the process of repairing or rebuilding a Ventoux engine and there is anything we can help you with (technical information, any documentation, return of experience, anything), you can contact us or send us an email to info@jgclassics.com where I will be happy to share any information that can help you.

Third anomaly (this time not a malfunction, but an anomaly):

Once the engine was rebuilt – with about 90% of its components new or repaired – everything seemed normal. Bench tests for a month and about 400 km of running-in on the road with no problems, no leaks, no fluid or compression losses. Everything seemed fine. We were happy with the result of the assembly. Until, in a new trip to the highway, appeared exactly the same symptom: oil level drop, it seemed to be coming out to the outside, and it seemed to come out “everywhere and nowhere” at the same time. No gasket was broken or badly assembled. And only on the highway. As if this car dragged the “curse of the fast lanes”.

Fortunately, this time as the engine was being tested, we were following up very meticulously and observing values and engine status at very short intervals, so nothing happened beyond the realization that the oil level had dropped more than expected -even for a running engine-, and the simple replenishment to the right level: but knowing that it was evident that there was something to finish adjusting.

The clean and new engine made it possible to identify the source of the “oil spray”: the drain hole of the clutch bell. That is, the rear exit of the crankshaft towards the gearbox, where there is no oil seal on Ventoux engines. So the oil was coming out of the part of the crankshaft that faces the gearbox. And we saw that oil was coming out of there when we maintained a high and constant engine speed. In order for the “spray” or “airbrush” effect to happen, the driving wind did the rest.

In any case it seemed impossible that, with everything new in the engine, the same symptom would repeat itself before and after the rebuild. With everything changed, it could be said that the engine was literally “another” engine than before.

But it was obvious that there had to be a common factor between the “before” and the “now”.

And then the question came up, "Has anyone looked at the breather tube on this engine?"

Upon removal and close examination, the culprit was revealed: The inner area that acts as a “stilling chamber” – so that only gases and no oil escape – was completely clogged by a thick mass of dried oil and carbon build-up accumulated over 60 years.

The engine breather was literally clogged. In the three photos above you can see the process of cleaning the rocker cover (using gasoline and then an industrial water-based engine degreaser). Pequinsa’s. You have it in this link )

After cleaning of the rocker cover breather

Cleaning the breather alleviated the problem, and for the first time in years on this engine, we could perceive – at last! 😊 – how gases were coming out of the breather (you can feel it by simply bringing your hand closer with the engine idling).

But this did not completely eliminate the problem. Although we saw that we were on the right track, we were still seeing some oil coming out of the crankshaft in the clutch bell. Less than before, but some. So it seemed that in our engine the rocker cover breather was insufficient. In our particular case – andonly certainly in our case – it was necessary to replace the closed rocker cover oil plug with a vented one, of the type used on some Ventoux engines (such as the 670-04 the Renault 4CV and or the Renault Juvaquatre). I will explain why later.

Our particular case. Why (surely) our Renault dauphine needed a vented plug instead of the usual closed one.

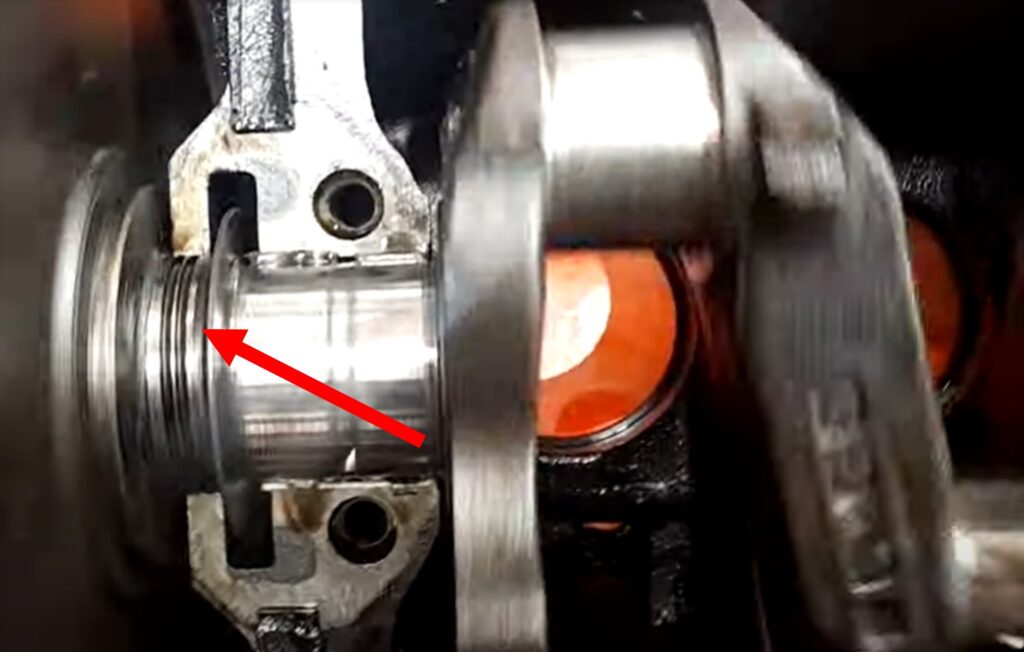

The reason – in our particular case – probably lies in the fact that the new crankshaft installed – coming from old stock – is of the “fine spline” type, and not of the “pigtail” type of the original Gordini (670-05 engine). This is the machining on the crankshaft outlet that keeps the oil from flowing out of it (just as a drill bit displaces the drilled material backwards).

The fine spline crankshaft is somewhat less effective at retaining oil and possibly requires additional venting, like the 670-04 engines to ensure that there is no overpressure causing oil to leak out of its splines. We fitted that crankshaft because of material availability, and because although it was not exactly the same as the 670-05 Gordini engine it is technically usable and above all it was NEW unused (a real unicorn 😊) .

This is certainly a hypothesis, but the facts support it: Now, with the cap vent clean and the vented cap installed, the problem disappeared completely, confirmed after a route of more than 400 km in all kinds of conditions (car loaded with three people and luggage, highway, mountain pass at 1500 m, altitude, etc.).

Summary

- In the first failure (breakage of the front crankshaft seal), the seal was not the cause, but the victim of the overpressure.

- En la segunda avería (la catastrófica), el aceite probablemente escapó por la parte trasera del cigüeñal, a través de la estría tipo “cola de cerdo”. Reparado el retén de la polea de cigüeñal, la única vía de salida a la brutal presión interior -debido a que el único respiradero disponible estaba completamente obstruido- eran las mencionadas estrías.

- In the third anomaly, and working only with the rocker cover breather -once it was cleaned- and non-vented cap version, the oil came out again from the rear of the crankshaft (clutch-gearbox side), due to internal pressure in the crankcase. Perhaps manageable with the original “pigtail” crankshaft of the 607-05 Gordini engine (more modern and effective in retaining oil) but still too much pressure for the less effective “smooth spline” crankshaft to contain the oil leakage and therefore more sensitive to the slightest overpressure. Overpressure which, eliminated by the vented plug of the 670-04, led to the complete solution of the problem.

Conclusion

The correct ventilation of the crankcase in Ventoux engines is a critical point to check, especially in these vehicles (Renault 4CV, Dauphine, Gordini), all of them with more than 60 years of experience, where it is easy to find partial or total obstructions in the ventilation ducts that also trust all their efficiency to the simple direct exit to the atmosphere.

If you notice that your engine is leaking oil that you cannot explain due to an internal engine problem or you observe leaks that seem to have no logic as to the exit point, check the crankcase ventilation because you may be in for a surprise and you may be able to solve your problem relatively easily.

In the next installment, I’ll give you more details of the crankcase ventilation and breathing system of the Ventoux engines and what solutions Renault adopted and what solutions Renault adopted during the different stages of its life.